What We Do | Manufacturing

Manufacturing Innovative Circuitry Technology

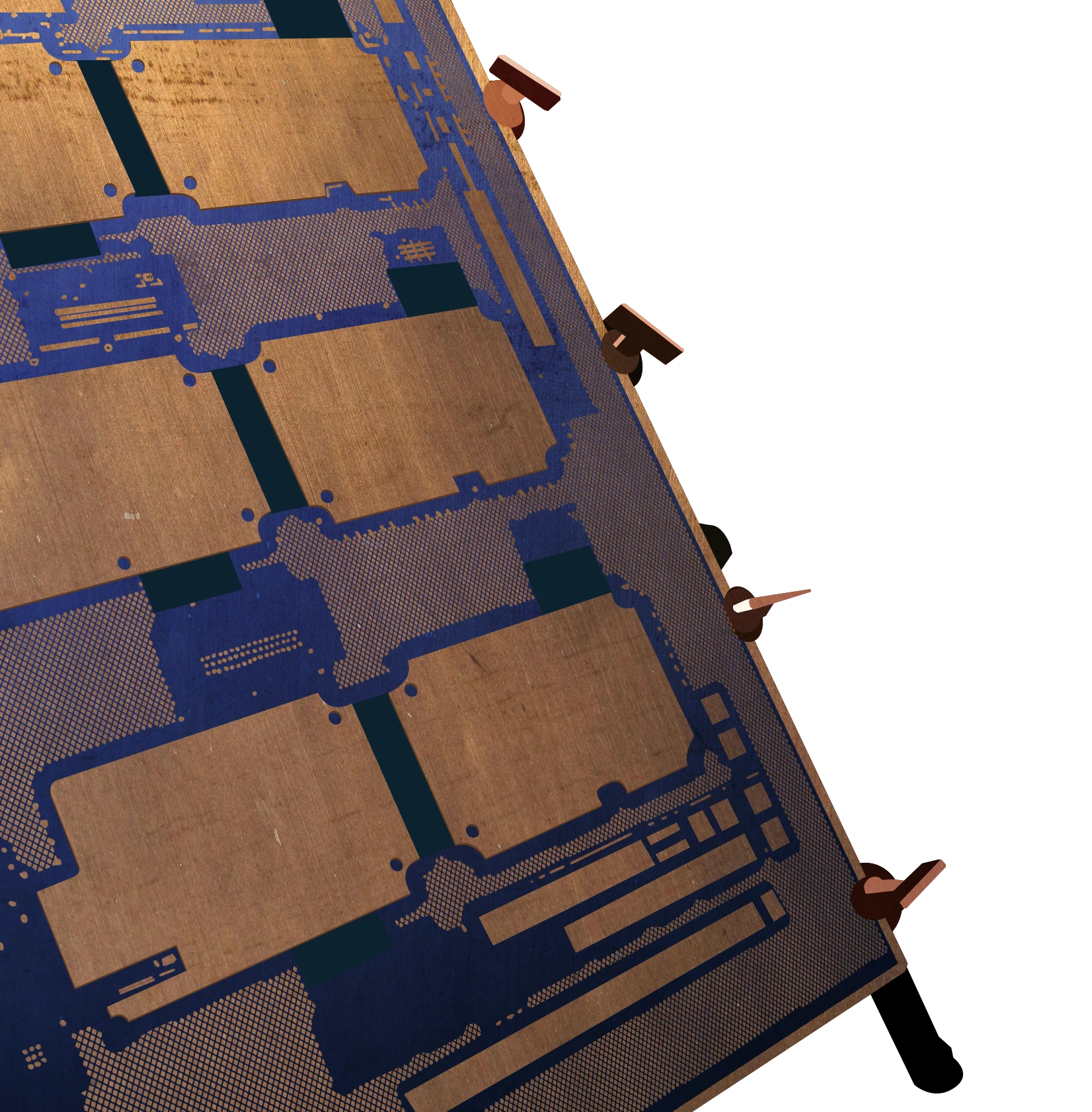

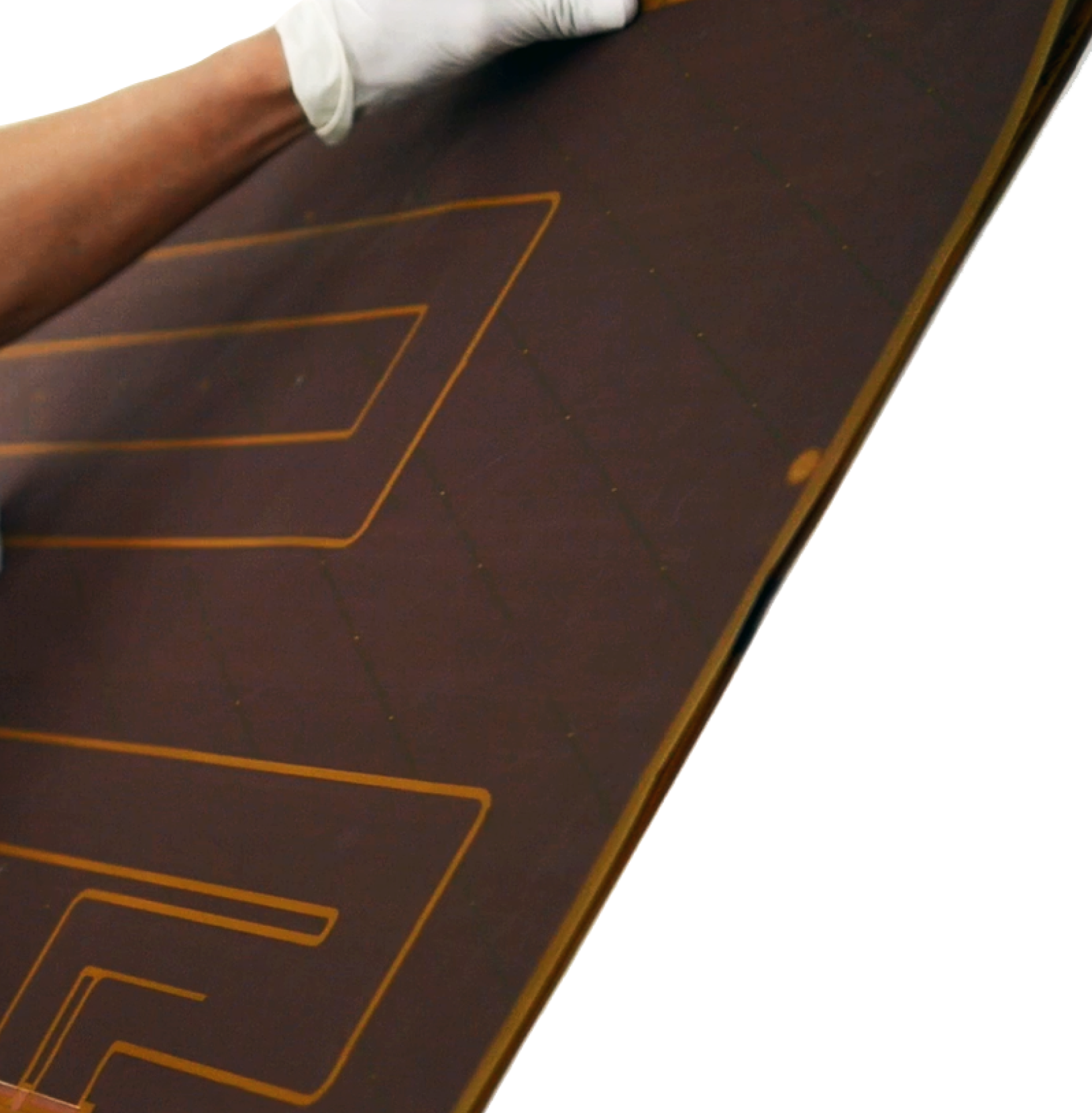

Pioneer manufactures innovative rigid, rigid-flex and flex circuit boards that power the future now in deep space, near earth orbit, aviation, and defense.

We Can Do It All

We Got You Covered with all the Standard Capabilities

Many of our assemblies are custom built to our customers’ needs. Our rigid, rigid-flex and flex assembly service typically involves the installation of connectors and other passive components onto our flex and rigid-flex parts to deliver high-quality, reliable advanced PCB technology solutions. Our assembly process also includes encapsulation, conformal coating, stiffner installation, potting of connectors, assembly forming heat sink bonding and electrical testing.

Manufacturing Capabilities

Giving You More Possibilities

High Layer Count

Standard Vias

Microvias

Bonding Options

Controlled Impedance

Thermal Management

EMI shielding

And More..

Tailored to Fit Your Needs

Through our years of experience, Pioneer Circuits has been able to optimize our PCB manufacturing workflow. As a leading printed circuit board manufacturer, we understand the importance of making sure everything runs smoothly while eliminating as much waste as possible. Each PCB manufacturer has their own version of a traveler that follows the board through each step of the manufacturing process, giving the technicians information on the part and what needs to be done. Pioneer Circuit’s PCB board manufacturing process is optimized by strategic organization by part numbers on our travelers. We continually adjust our travelers and workflow to make improvements, ensuring a smooth flow of our part from the beginning to end of the manufacturing process.

Assembling High Quality PCBs for you

Find out more on how our assembly team can help you